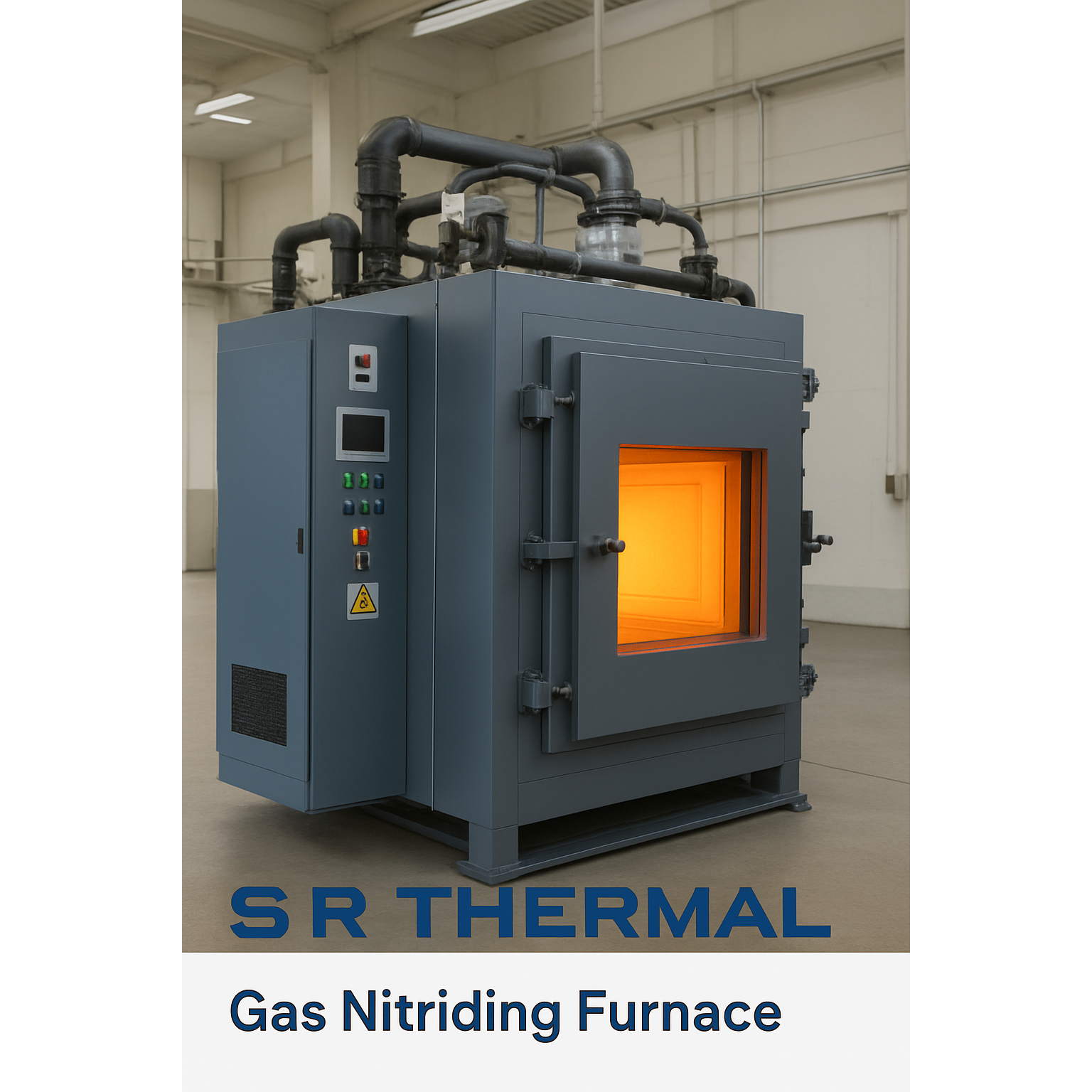

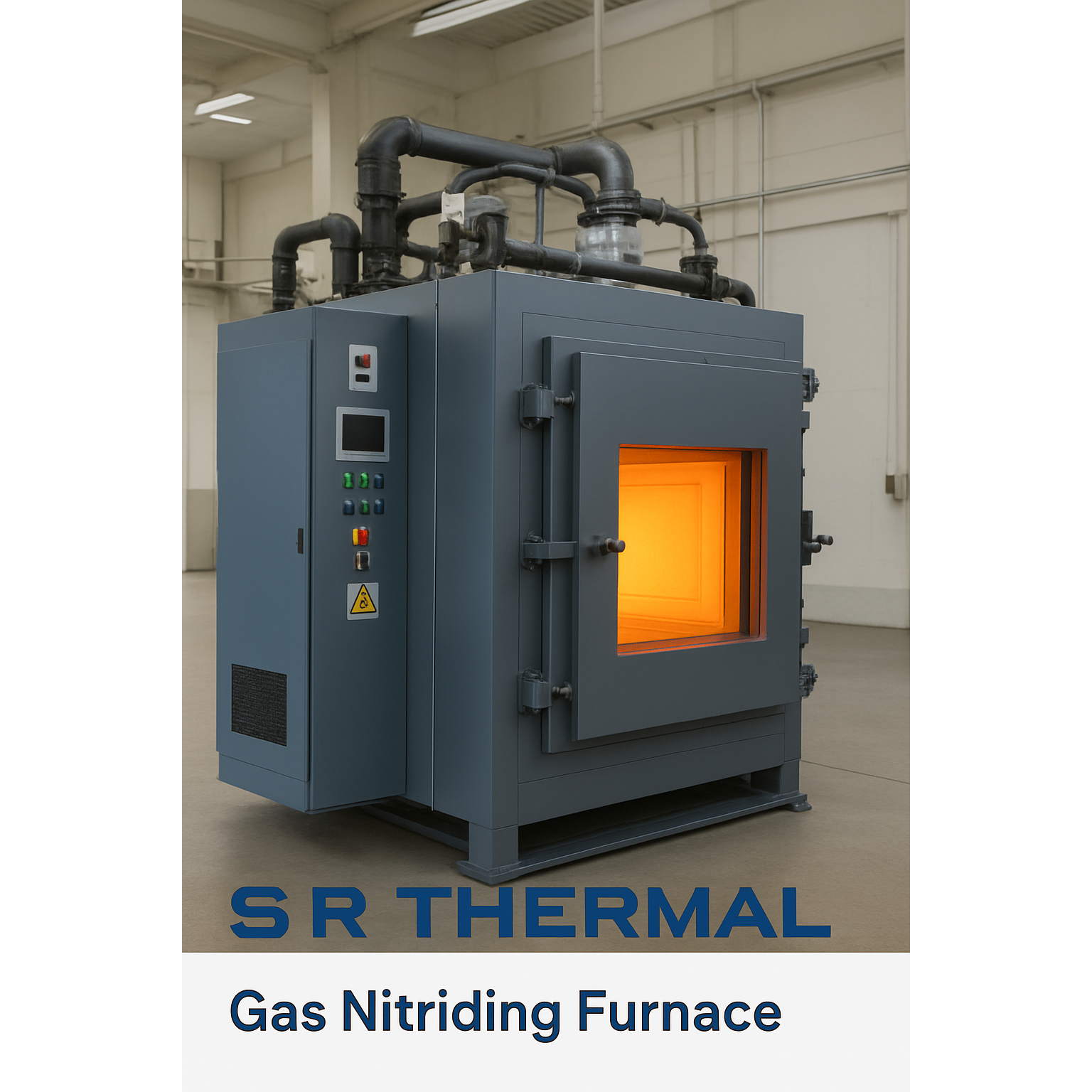

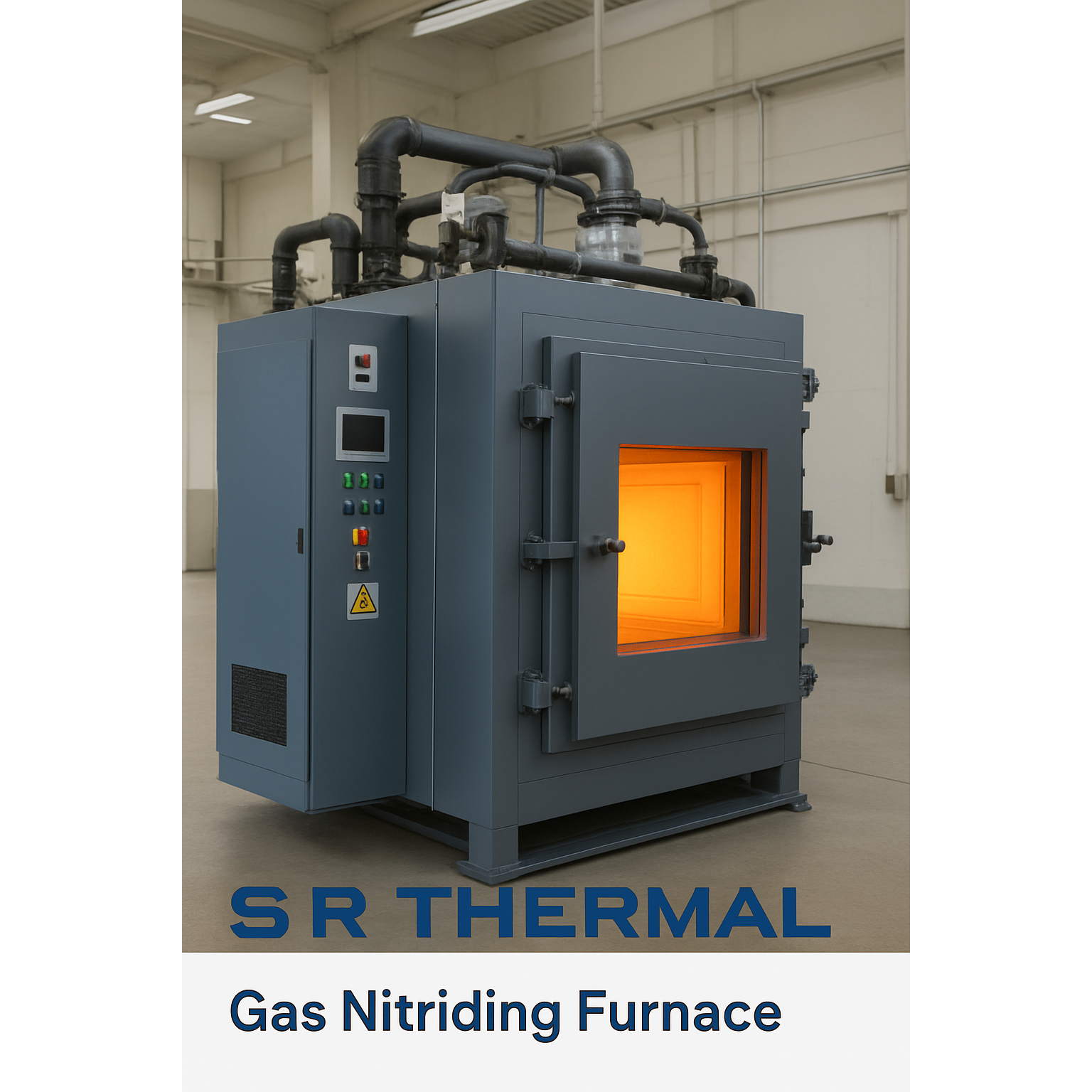

A Gas Nitriding Furnace is an advanced heat-treatment system designed to enhance the surface hardness, wear resistance, and fatigue strength of steel components. Using controlled nitrogen-rich gas atmospheres—typically ammonia (NH₃)—the furnace diffuses nitrogen atoms into the metal surface, forming a tough, high-performance nitrided layer without causing distortion. This makes gas nitriding ideal for precision components that require long life and superior mechanical properties.

Our gas nitriding furnaces are engineered for automotive, aerospace, tool & die, machinery, energy, and engineering industries, providing consistent results across global manufacturing standards. With precise temperature control, automatic gas flow systems, and advanced PLC automation, these furnaces ensure uniform nitriding depth, excellent repeatability, and stable metallurgical performance.

Built with high-quality alloy chambers, energy-efficient heating systems, and safety interlocks, our furnaces support single-stage and multi-stage nitriding, including nitrocarburizing and post-oxidation processes. They are suitable for a wide range of materials such as alloy steels, tool steels, stainless steels, and cast irons.

Whether you're improving component durability, enhancing corrosion resistance, or minimizing wear in demanding environments, our Gas Nitriding Furnace delivers world-class heat-treatment performance trusted by industries worldwide.

gas nitriding furnace, nitriding heat treatment, ammonia nitriding, industrial heat treatment furnace, nitriding equipment, nitriding process machine, surface hardening furnace, global nitriding systems, nitrocarburizing furnace, heat treatment technology