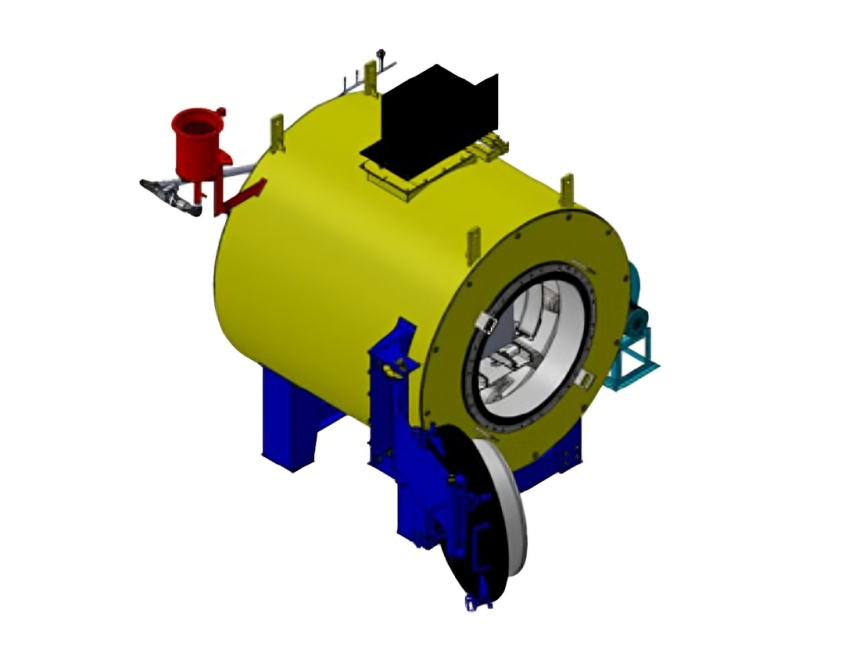

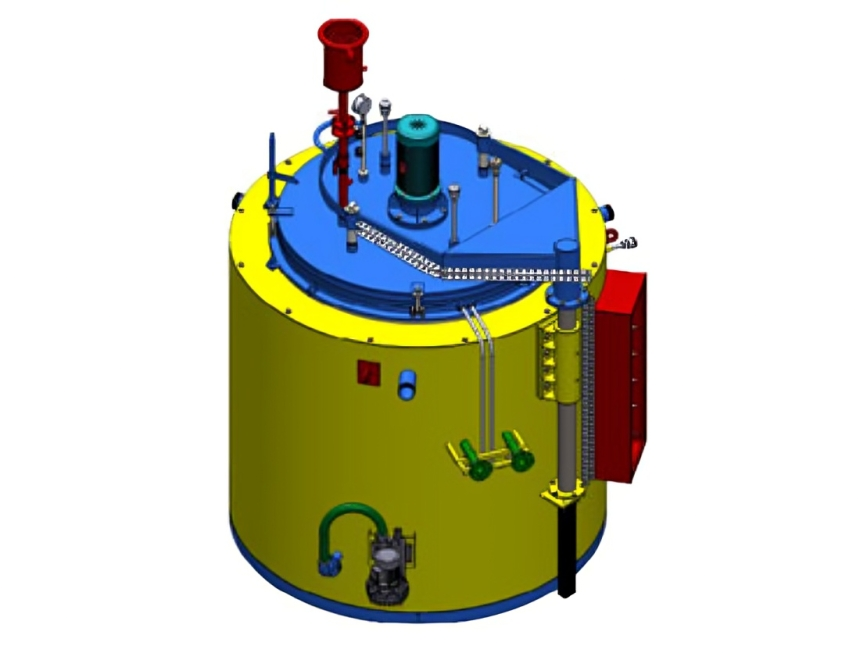

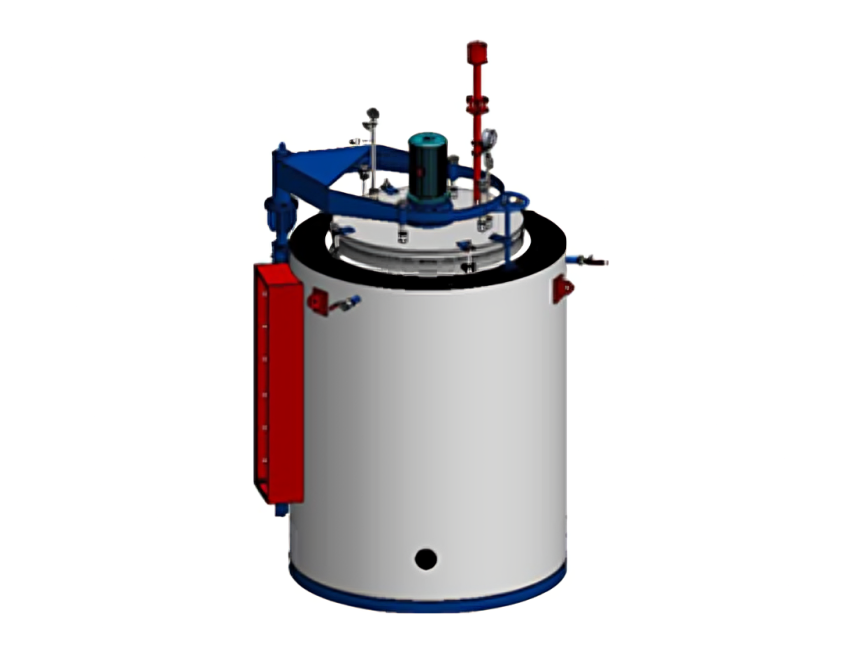

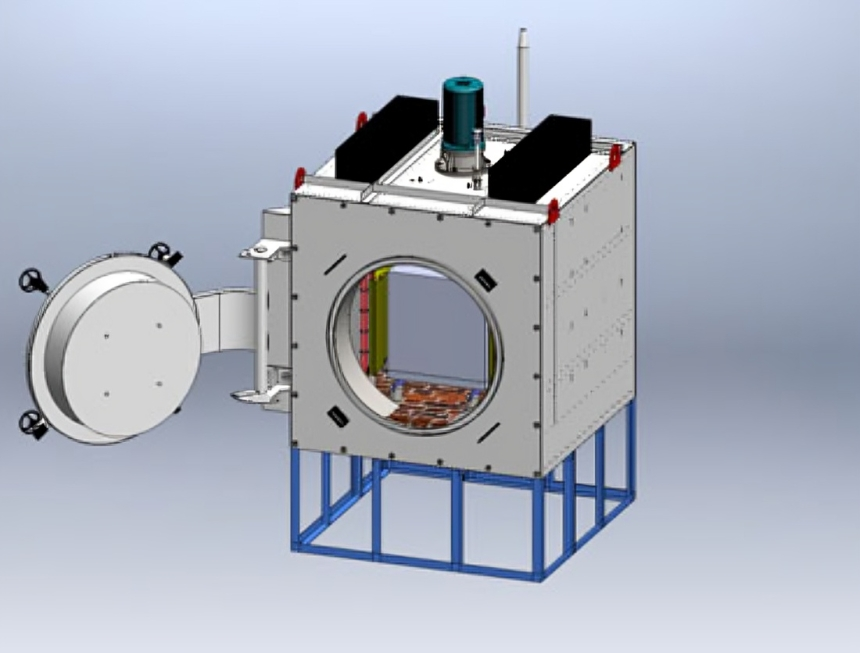

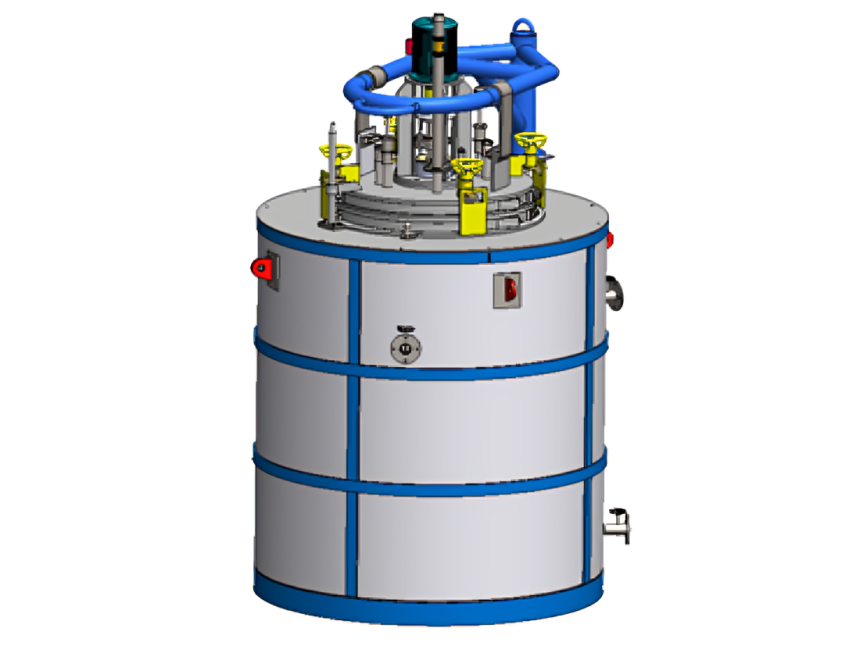

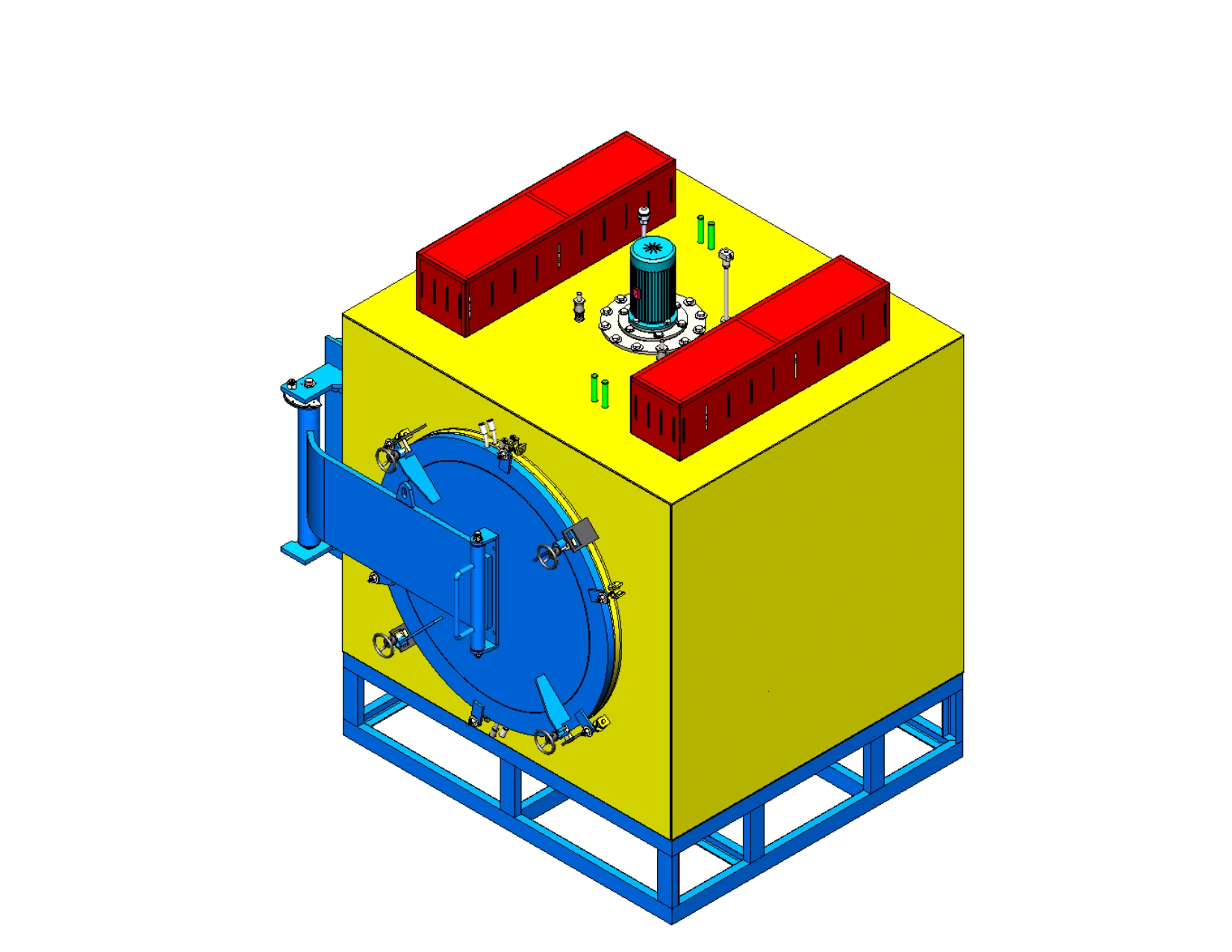

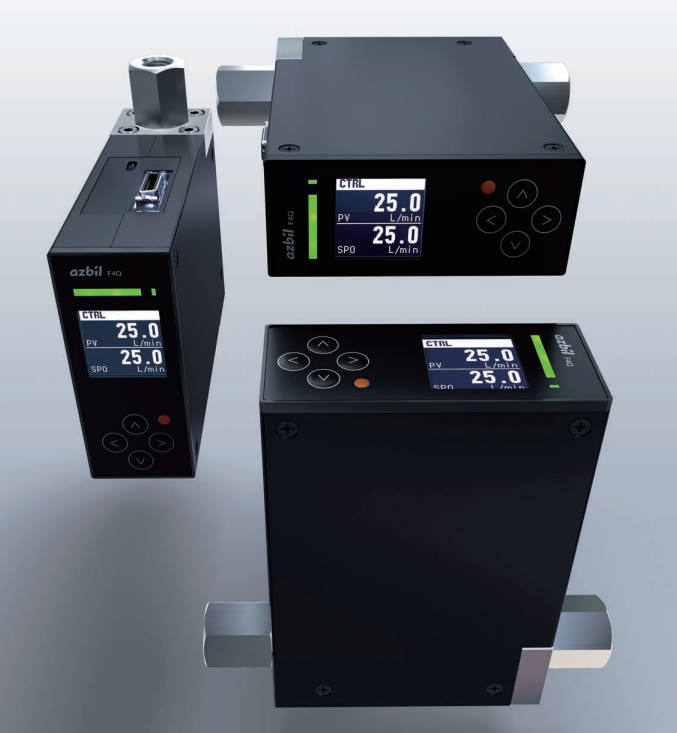

Horizontal Type With Retort Gas Nitriding Furnaces by S.R. Thermal Solution are engineered for efficient, uniform nitriding of various components with precise control over temperature and gas flow. The Inconel retort ensures long service life, while the horizontal design offers easy loading/unloading and smooth operation. Ideal for high-performance, repeatable heat treatment cycles. Process Gas Nitriding/ Nitro-Carburizing – Nitriding+ Oxidation – Preheating – Tempering/ Stress Leaving Specification: 7' HMI+PLC SCADA system Temperature PID controller system Heating - Thyristor controller KN-controlling system Recirculating fan Rapid cooling system Gas panel - Ammonia, Nitrogen, Carbon Dioxide, LPG, & Steam Application: Crankshafts Aluminium Extrusion Die Fuel Injectors Piston Rings Gears & Shafts