“A gas nitriding furnace machine—also known as an ammonia nitriding furnace or gas nitride furnace—is an advanced surface hardening system that diffuses nitrogen into metal components to enhance wear, fatigue, and corrosion resistance.”

A Gas Nitriding Furnace Machine—also called an Ammonia Nitriding Furnace or Gas Nitride Furnace—is a high-performance heat-treatment system designed to improve surface hardness, wear resistance, and fatigue strength of steel components. Using controlled ammonia gas atmospheres, these furnaces create a uniform nitride layer without distortion, making them ideal for automotive parts, aerospace components, tooling, and heavy machinery.

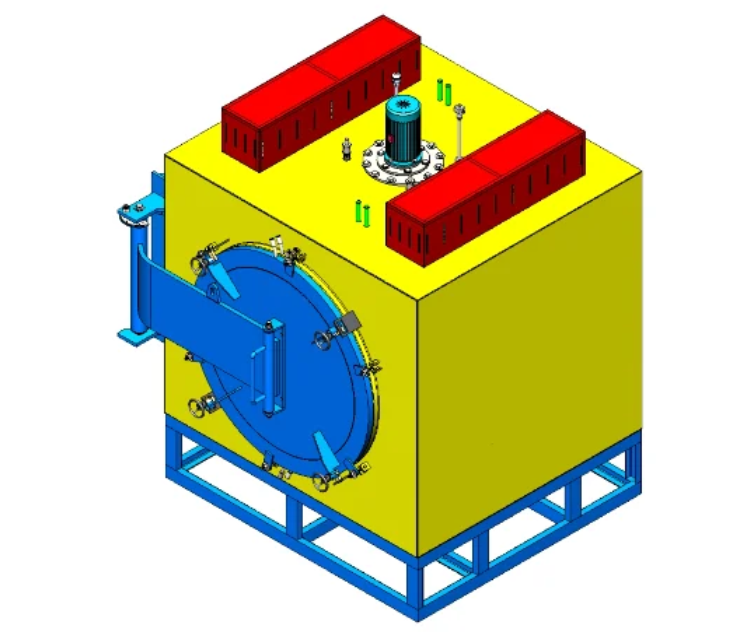

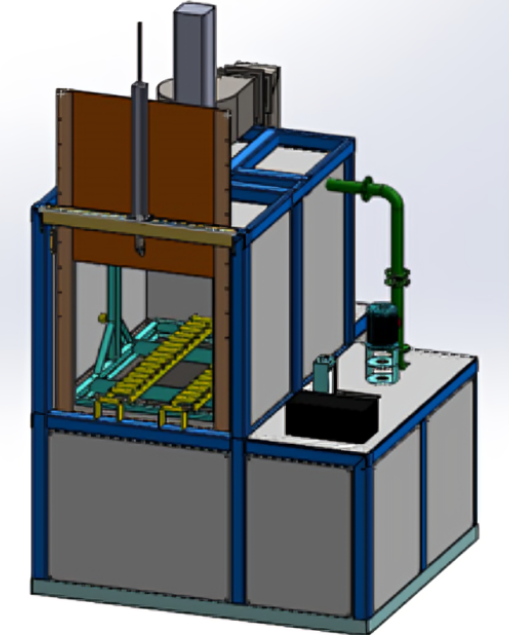

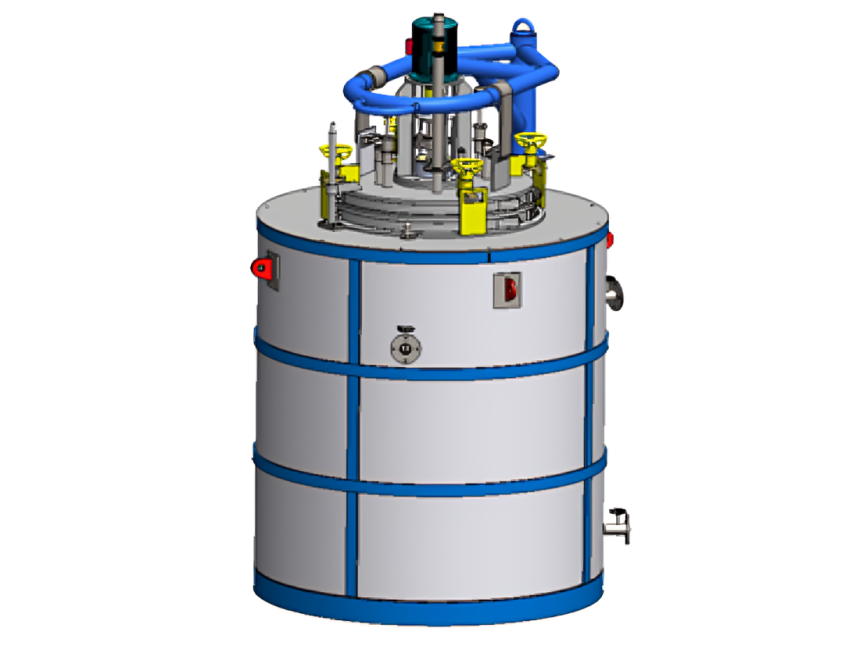

Available in pit-type, box-type, and vacuum-purge designs, gas nitriding furnaces deliver precise temperature and gas flow control for consistent case depth and quality. Modern systems are engineered for energy efficiency, atmosphere safety, and low maintenance operation, ensuring long service life.

Globally, gas nitriding technology is recognized as a cost-effective alternative to hard chrome plating and carburizing, with growing demand across the U.S., Europe, and Asia. Whether you need batch production or continuous processing, a nitriding furnace enhances product durability and reduces lifecycle costs.

Gas nitriding furnace

Gas nitride furnace –

Ammonia nitriding furnace – refers to the ammonia-based method

Pit-type gas nitriding furnace – vertical/long-part design

Box-type / chamber-type gas nitriding furnace – horizontal, general-purpose

Vacuum-purge gas nitriding furnace – specialized batch variations

Vacuum nitriding furnace / Glow nitriding furnace / Ion nitriding furnace

Gas soft nitriding furnace – lower intensity gaseous nitride ,

Ferritic nitrocarburizing (FNC) furnace ,

Gas nitrocarburizing furnace ,

Nitriding furnace,